FAMOUS FOR THEIR RELIABLE ROBUSTNESS – COMPRESSION CRUSHERS FROM IMS ENGINEERING WITH ATA’S BEVEL GEARS

Selecting the right crushing plant equipment tailored to specific mining needs is paramount for peak efficiency and cost-effectiveness. Equally crucial are the technical components within crushers, notably gears, which significantly influence performance. IMS Engineering relies on ATA Gears for premium bevel gears, ensuring unparalleled performance in their compression crushers.

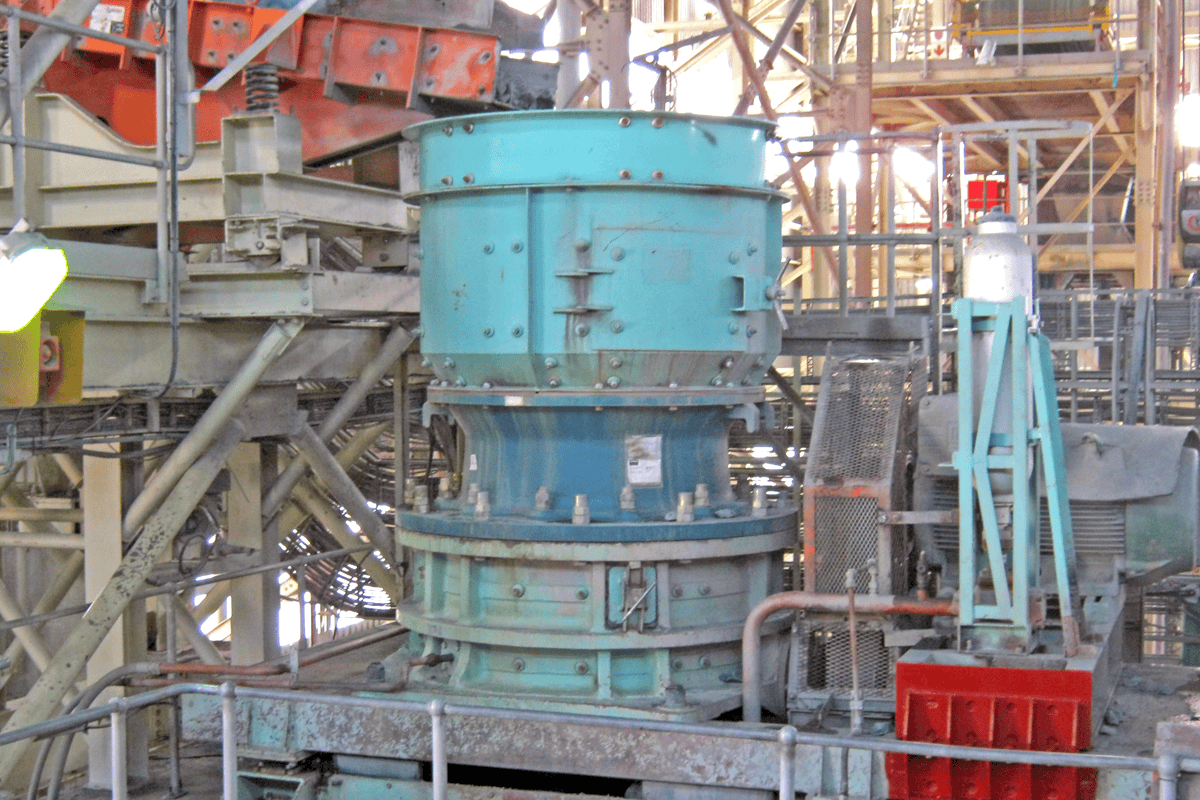

Powered by a license agreement with ETCL (EarthTechnica Company Limited) in Japan, the comprehensive crushing lineup of the South African company IMS Engineering encompasses a range of models such as jaw crushers, gyratory crushers, cone crushers, impact crushers, and roll crushers. Each crusher type boasts distinct attributes and benefits, with selection depending on specific applications and material properties. Resilience in challenging hard rock scenarios, from granite, basalt, gneiss, greywacke and iron ore to slag applications is what IMS Engineering’s crushers are all about.

ATA’s bevel gears as integral components

Vincent Potgieter, Engineering Manager (Comminution Products) at IMS Engineering, shares an important factor behind the success of his company’s solutions: “Currently, we partner with ATA Gears for bevel gears often utilized in our cone and gyratory crushers. ATA’s bevel gears are integral components in our Compression Crushing lines.” He further explains: “Our overarching goal across all solutions is to maximize throughput and reliability, ensuring tangible ownership benefits. ATA’s gear solutions certainly play a role in achieving this objective.

ATA Gears Sales Manager Pentti Hallila comments on the successful cooperation between his company and IMS Engineering: ”We hope to be able to help them to achieve their goal of increasing their market share as a leading solutions provider in the mineral processing industry. Being thoroughly familiar with the gearing designs of ETCL Kawasaki through our cooperation with them for some 30 years is certainly a big asset.”