Close cooperation with subcontractor – a way of speeding up product launches

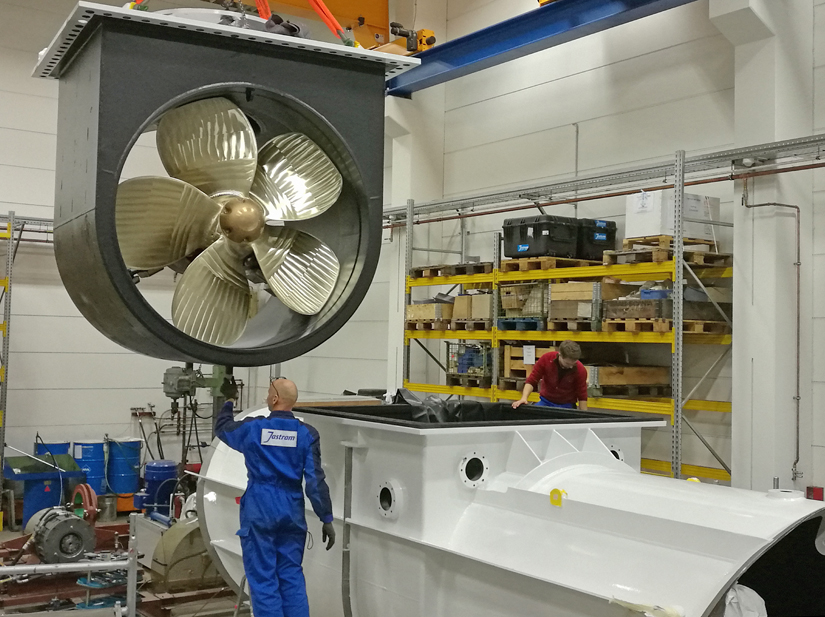

Improving the maneuvering capabilities of sea vessels – that’s what Jastram has set its sights on since 1950. To that end, the Hamburg-based manufacturer has developed transverse thrusters, high-efficiency rudders and rudder propellers for increasingly demanding customer needs. ATA’s reliable gear engineering knowhow has supported the company in its goals.

Jastram’s Managing Director Gerhard Erb is very clear about Jastram’s core competence and its partnership with ATA Gears: “Our cooperation dates back to 1980. That’s when we received our first ATA-made spiral bevel gear sets for our transverse thruster gears.”

Jastram is a family business originally founded in 1889 in Hamburg, Germany. Until 1960, the company produced up to 500-HP-sized diesel engines, but in 1950 it had begun to develop technologies to improve the maneuvering capabilities of vessels. This meant adding transverse thrusters, high-efficiency rudders and rudder propellers to the product base.

“Our first transverse thruster was installed on a vessel in 1955. Since then, more than 5,000 of our transverse thrusters between capacities 50–1,650 kW have been taken into operation worldwide,” Mr Erb says.

“Our first transverse thruster was installed on a vessel in 1955. Since then, more than 5,000 of our transverse thrusters between capacities 50–1,650 kW have been taken into operation worldwide,” Mr Erb says.

Jastram Forschung GmbH was founded in 1970 to concentrate on research and development. From that time onwards, it has focused on innovating groundbreaking noise-reduction technologies for tunnel thrusters. ”That’s where our market position is solid today,” Gerhard Erb declares. “We supply our products to commercial and military vessels, as well as sophisticated superyachts. Customer orientation is one of our key strengths – and the reason for our success.”

Coinciding interests

Jastram is known in the market as a supplier of reliable, first-rate thruster gears. To a great extent, this reputation depends on the quality of spiral bevel gears that are key components in transverse thruster gears. According Gerhard Erb, as a manufacturer of spiral bevel gear sets, ATA Gears is a perfect partner for his company. “With its respectable over 80 years of experience, ATA continues to improve their processes and invests in research and development activities. ATA’s cutting and hardening technologies are a daily proof of the company’s capability to provide fully customised and reliable power transmission.”

The supply of transverse thrusters with noise-reduction technologies to superyacht shipyards is what Jastram specialises in. These challenging clients only qualify gears with low vibration levels. Due to their dimensions, the superyachts often require up to four transverse thrusters to keep the yacht stationary or to guarantee safe maneuvering in tight ports. Especially when the vessel is controlled by a DP (Dynamic Positioning) system, the thrusters are in operation day and night. Hence, minimum noise and vibration levels are critical in reaching the comfort level specified for such yachts. This is where the contractor/subcontractor development efforts meet. What Jastram and ATA have in common, according to Gerhard Erb, is that they continuously strive to improve their products. “As medium-sized, family-owned companies, we share the same goals and values.”