Sustainability is not a new invention

but Brunvoll want to know more about it every day

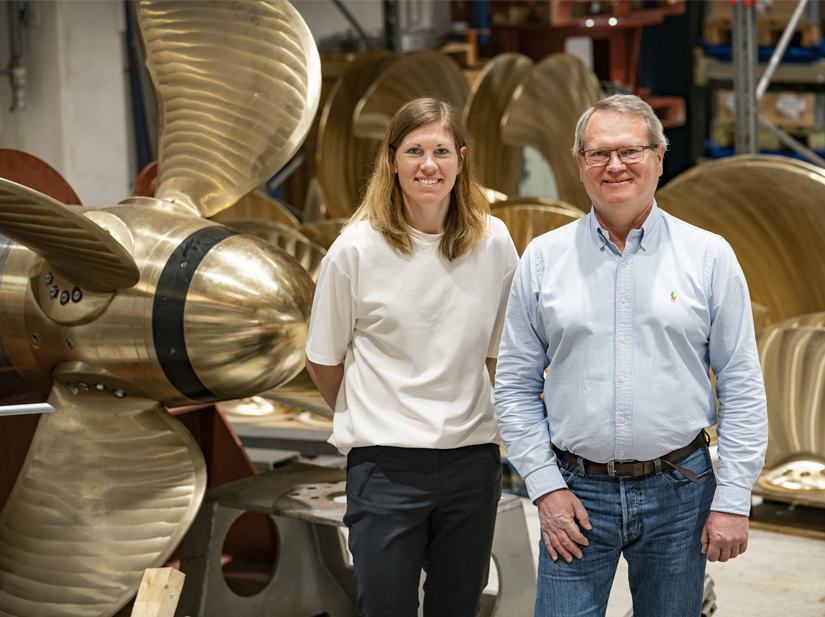

It is the declared intention of propulsion system and thruster designer and manufacturer Brunvoll to be at the forefront of sustainable development. They justifiably feel they are providing reduced life-cycle costs, high operational reliability and reduced emissions to yards and ship owners in the global market.

The main environmental issue with shipping is pollution. Hedda Nordby Krogstad, Senior Engineer Material Technology and Mechanical Design, explains this: ”If we can achieve a state where there are no emissions from the ship, then we still may have problems caused to the sea by the seals in the gearboxes. And we have the problem of noise pollution – and the fact that it takes a lot of material to build a ship. Those three problems will still be there when you have solved the energy problem, so we need to work on all of them.” That is what Brunvoll are determined to do – and have been at it for decades before sustainability became such a buzzword.

Gear optimization is on the agenda

Brunvoll’s co-operation with ATA Gears consists of both ordering gears and joint development projects. “Normal day-to-day operation with ATA is ordering gears calculated by ATA’s experts and with drawings prepared by Brunvoll. We have been using ATA´s bevel gear expertise for 40 years, which is a long time – and a lot of valuable experience has been gained on both sides,” Strategic Purchaser Bård Stener Brunvoll declares.

According to Bård, cooperation between the two companies was taken to the next level when they started on gear optimization. Both learned quite a lot about gears and gear geometry and how to get more power out of the gears. “It was a good step,” remembers Bård and continues: “We call it sustainability now, but over the years we have tried to minimize the use of raw materials, for instance, to use optimum-size open die forgings shaped as close as possible to how the finished gear would be. And I know that ATA has done quite a lot regarding heat treatment.”

Bård likes to correct one potential misinterpretation: “The aim is not to make the gears smaller. The gears may even become bigger to achieve the wanted power. Environmentally an optimal blank is important to save on raw materials. That’s what we are aiming at.”

How the gears are produced is equally important. There are several ways to produce gears, for example using traditional gear cutting and grinding machines. Today the technology favors advanced 5-axis machines, in which ATA Gears has also invested a lot. The point is to use new technology to make the process of producing gears even more sustainable regardless of the production method.

Actively collecting more data – and acting on it

Brunvoll have meticulously mapped their own emissions. “We have met scope 1 and 2 of our greenhouse emissions, that is, the emissions from our own facilities and our own energy consumption,” explains Hedda. “We set some targets to decrease the emissions by eliminating those points where we have emissions, like company cars as well as process and so-called fugitive emissions. We still need to decrease our energy intensity, which is energy consumed divided by company turnover. That is the footprint from our own facilities.”

In scope 3 part Brunvoll aims in the first round to get more data on transportation of goods. “We already have the figures from air travel,” declares Hedda. “The travel companies can nowadays provide you with calculations of the emissions from using planes. Now we want to get corresponding data from logistics companies. The regulations require them to supply these figures at some point.” So, more important data is on the way.

Hedda explains the bigger picture: “Some of the largest sources of emissions in the world are from transportation and production of materials, and these cannot be solved by the companies alone. We need the help of governments and subsidies, meaning we need to create a ripple effect. If we start to disclose how much transportation we use and the estimated emissions from these, and also disclose how much recycled or raw materials we use and then recycle, we can see when it is reduced and this will motivate further changes. That is why it is really important to have the documented and exact figures from the entire supply chain.”

Preparing for the future to make it better for all

“We have asked all our main suppliers to provide us with information about the input materials, how much of their material was recycled. Very few have been able to do this and that needs to change. We really need to get to the point where suppliers not only know these things about their materials but can also provide the buyer with the concrete documentation. This has been considered tedious and unnecessary, since there is no money in documentation, but it will become a condition for making the sale,” says Hedda.

“In the future, if and when the carbon tax comes into force, you will be way ahead if you have already started the mapping process. In this, a partner like ATA Gears can really help us a great deal. We want to know the figures now, if the carbon tax becomes a reality, we will need to be able to predict how much tax we will have to pay to produce our products. Using the risk-based approach will make us more resilient,” Hedda declares.

Waste or valuable material?

“How much material we use per category and how much is recycled. Having some say in what happens to our waste is important, making sure it is recycled. We have started to ask the scrapyards what eventually happens to our products. People need to change their views on scrapyards. They are depositories of a lot of wealth,” continues Bård. Most of the scrapyards are located in low-cost countries like India. Bård asks why this is so. Do they need to be? The shipping cost for recycled material is high, yet it is valuable material. Why are there not more scrapyards located nearer the production facilities in Europe, for example in Finland or Norway? A good question.

The importance of manufacturing products that last

The most common flaws in thrusters are leakages and electrical faults. Some electrical faults can be remedied remotely, but problems requiring drydock are those with the seals and in some cases bearings or gears. As in a car, some parts, like seals, wear out. All parts in a thruster or propulsion system, for example, have a calculated service life. By using the accepted service parts and the expert service technicians and with right service intervals, there should be good possibilities that the thrusters could operate for 30 years and beyond.

One of the big challenges in the marine industry has been the lubricants. Happily this has been solved. The so-called “friendly lubricants” – environmentally friendly but deleterious to rubber seals – were the first step. Product development on the seals was called for and now Brunvoll has a solution, a solution which is sustainable from the point of view of both the seals and the environment.

Making some noise about noise

Noise is an important factor in product development, but so far rather less so from an environmental perspective. The emphasis has been primarily on the noise levels for passengers on board cruise ships and in the working environment on merchant vessels. These are important health and safety issues and merit consideration. However, both Hedda and Bård believe that the requirements to reduce noise levels will eventually demand consideration for wildlife, for example if a ship operates near an area where there are whales, it is important not to disturb them and their communication in the ocean.

The noise comes from steel and various components hitting or grinding against each other and underwater it carries far. “How we shape the propeller has an impact on the noise in the ocean, and we need to consider it more in the future. Brunvoll has a product called the super silent thruster, which reduces the noise considerably,” Bård explains.