Products

As ATA Gears’ customer, you can be confident of receiving the best solution for your power transmission needs. Almost 90 years of experience and close cooperation with industry leaders worldwide have taught us a lot about the requirements for all kinds of gears in various demanding applications. To meet the highest performance and reliability requirements, we control the entire manufacturing process in-house, including heat treatment. Our state-of-the-art process of gear design and manufacturing as well as the uncompromising quality control guarantee the quality of your product.

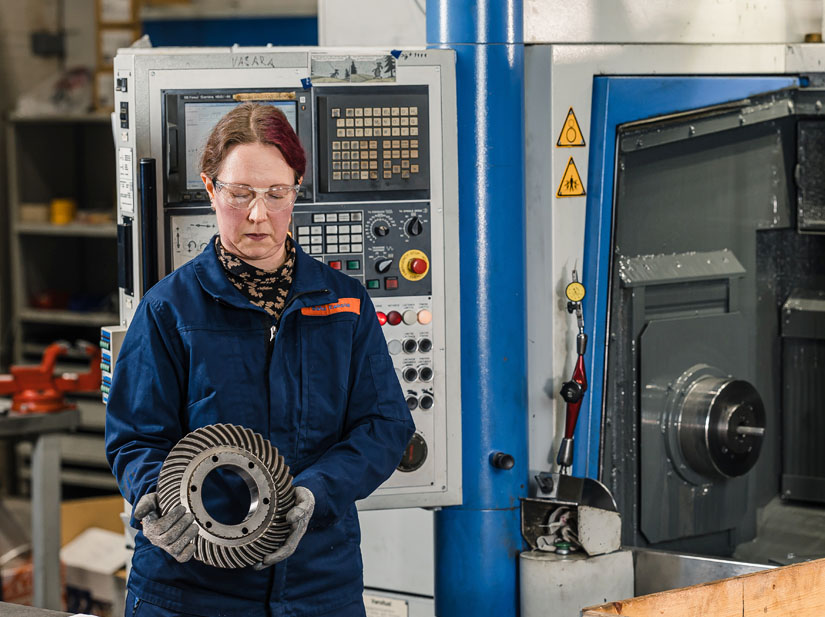

Geared power transmission components

ATA’s geared power transmission components are the choice of several global market leaders in their respective industries. Many critical processes rely on our bevel and cylindrical gears, and they are an important component in some of the coolest and most innovative power transmission solutions. ATA Gears keeps you in motion.

Capabilities and knowhow

Standard or non-standard tooth geometries, internal or external gears, freely selected module and helical/pressure angles, new innovative geometries… We can produce bevel and cylindrical gears using both conventional tooth-cutting methods – for example generating cutting/grinding – and state-of-the-art 5-axis miling methods. ATA’s process is organized to produce the specified gear product accurately and efficiently: raw material, gear design, heat treatment, NDT, everything needed to maximize the reliability and competitiveness of our customer’s product. With such a long history in gear making, ATA Gears has invested heavily in research and development and is 100% committed to gear excellence, for optimal performance and reliability in the final application.

Contact us – Your power transmission is our mission

We are proud to present some of our customer success stories. Read more about the challenges and the cooperation.