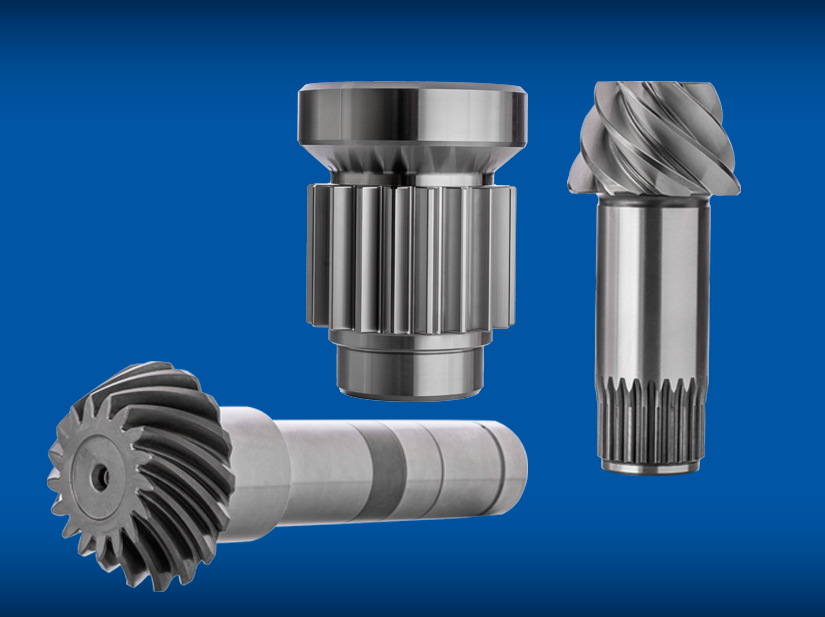

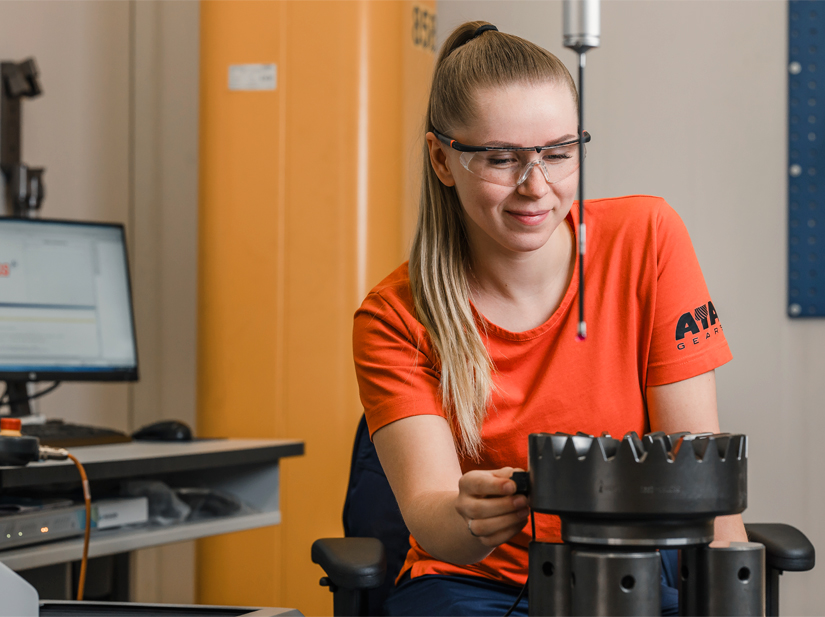

Capabilities and knowhow

ATA Gears can produce bevel and cylindrical gears for all kinds of applications using both conventional and 5-axis machining methods. Our manufacturing process is able to accurately produce the specified gear product: raw material, design, accuracy, heat treatment, NDT – all manufacturing stages are controlled in-house. Whatever the product or application, ATA Gears has the right machines and knowhow for the job. We also invest significantly and continuously in gear testing and materials development.