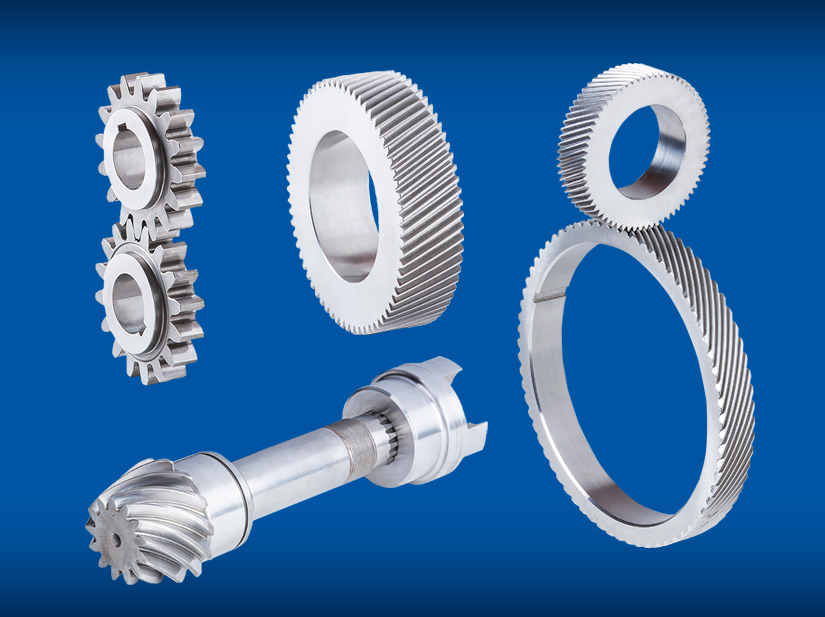

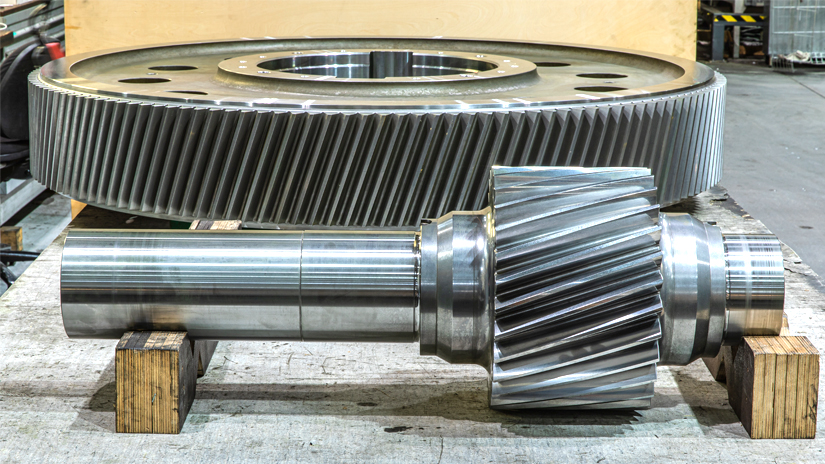

Cylindrical gears and splines

ATA Gears’ production capabilities and knowhow for cylindrical gears and splines are the result of decades of experience and development with all viable technologies – both traditional tooth cutting methods and state-of-the-art 5-axis machining methods. As pioneers of 5-axis machining for bevel gears, we are the technology leader in that field, and we apply this same knowhow in the production of cylindrical gears and splines.

The greatest advantages of 5-axis methods for cylindrical gears are that no special tooling is needed and the gear design is not restricted by the limitations of conventional gear cutting/grinding machines. So we can optimize tooth geometries much more freely and small-batch project with critical leadtimes become more economically viable. Basically all kinds of cylindrical gear geometries are feasible: spur, helical, double helical, crossed helical, curved tooth couplings, gear racks, etc. Splines of basically any geometry are also possible: involute, straight-sided and serration profiles being the most common. In addition to cylindrically-shaped spline connections, face tooth couplings are also feasible (e.g. Hirth coupling). With this vast capability, we can offer our customers complete deliveries, which often brings big benefits in the order process, classification and project management.