Gear design and optimization

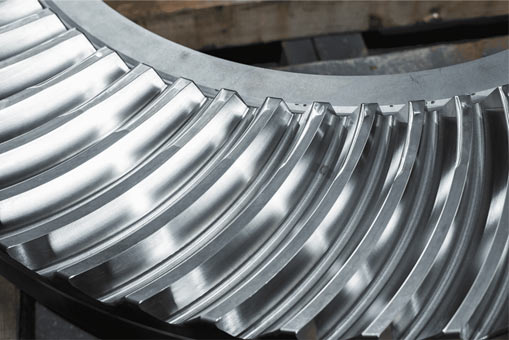

Depending on customer needs, we are able to carry out both basic tooth geometry and strength calculations as well as highly advanced gear simulation and optimization. Geometry and strength calculations can be carried out according to all common national and international standards as well as methods applied by classification societies. With our in-house gear design capability, we can guarantee full manufacturing compatibility already in the design phase, which is very important for cost-effective solutions.

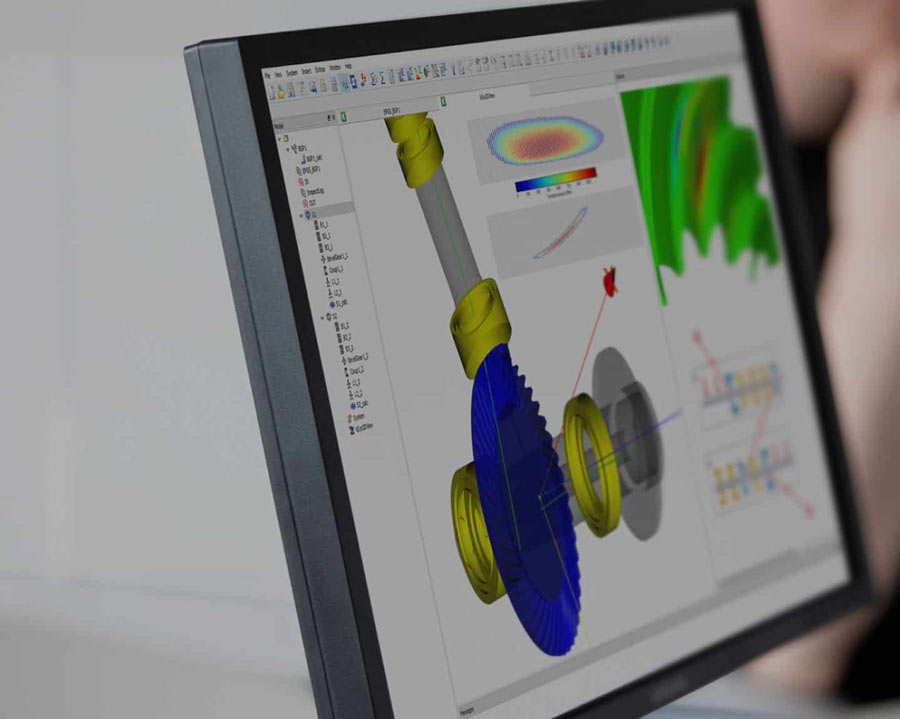

For applications with stringent requirements – regarding, for example, power density, noise and efficiency – we utilize our advanced gear simulation/optimization concept. This approach ensures significant improvement in the performance and reliability of a gear drive as the tooth micro-geometry – the tooth flank topographies – is designed so that proper tooth contact is maintained in all loading conditions. With our proven simulation-based design concept the tooth geometry can be optimized as a part of a system-level analysis, taking account of the effects of the entire driveline environment. A complete model of the gear drive is used to predict actual gear misalignments in various loading conditions.

Misalignments are used as input for tooth mesh simulation based on precise 3D models. This process gives the designer valuable insight into crucial tooth mesh properties, such as tooth stress distribution, dynamic behaviour, sliding speeds, flank temperatures and tooth backlash. The tooth geometry can then be modified specifically to ensure optimal tooth contact characteristics in all loading conditions. Our simulation and optimization concept enables more accurate assessment of various potential damage mechanisms. Applied at the design stage, these can further reduce overall costs through improved reliability, shorter product development time and faster assembly and testing processes.